Published by Brooke Sardella on 06/27/2022

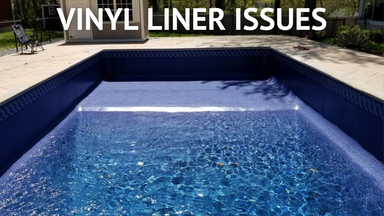

Vinyl Liners & Common Issues

Your vinyl liner transforms the entire look of your pool and gives it that beautiful blue hue, while also protecting bathers from exterior walls and the ground. Here, we’ll dive into how pool liners are manufactured today and common issues that could occur.

In the past, a liner may last nearly 25 years before a replacement was needed. While they don’t last nearly as long these days, there are a few reasons why this is a good thing! Older style liners that were sold in the United States were filled with preservative chemicals that made them last longer but were harmful to both swimmers and the environment. Modern pool liners no longer contain these elements such as Phthalates, BPA, and heavy metals.

While liners today won’t last as long because of these safety regulations, there are still ways to invest in a quality liner. The difference between a high-quality and economical liner is that they are made with UV inhibitors, which prevent the liner from shrinking, fading, and becoming brittle under the sun. Investing in a high-quality liner like GLI will use this new technology as well as stain resistance to prevent permanent staining from poor water chemistry, dirt, and metal.

Common Issues

Wrinkles in Vinyl Liner

This is a well-known issue in the pool industry caused by improper water chemistry, typically low pH. When the pH drops for an extended period of time, the vinyl will start to absorb more water, which causes it to get larger and stretch down and away from the pool walls.

High sanitizer levels from bromine or chlorine are also a top contributor to wrinkles, along with pH stabilizers and cyanuric acid. These levels should be monitored to prevent this from happening. Unfortunately, as with wrinkles caused by low pH, the winkle damage can not be reversed by changing the chemistry and you will most likely need a new liner.

Pools using salt chlorine generators and/or pool covers are also more sensitive to wrinkles. To combat this, salt generators should simply be monitored regularly to ensure all levels are in their proper ranges. Then, when using an automatic cover, it is important not to cover the pool after chemical application until they have dissolved and returned to the recommended levels. The pool should also be able to vent every 24 hours.

Tearing your Liner

Another common issue is having a hole in your liner, usually due to an accident from something falling into the pool. Thankfully this is an easy fix that can be found in our blog Repairing a Vinyl Liner Tear.

Liner Out of Track

A liner out of its track is most likely to happen with an old liner that should be replaced, but can also happen to new installations as well. You can try to get the liner back into place yourself, by following our tutorial here. If the liner cannot stay in the coping and keeps slipping, you can also try a liner lock to retain the liner bead in the coping. Sharp corners are the largest problem areas for liner slipping. Liners will ultimately shrink as they age under UV damage because while there are those inhibitors designed into high-quality liners, they cannot deter this issue forever!

Draining a Lined Pool

Before you attempt to drain your vinyl lined pool it is important to know a vinyl liner pool should always retain 6-12 inches of water in the shallow end! This is because the liner will shift with the weight of the water in the deep end, pulling the liner away from the walls and causing you to need a new liner immediately. If you need to drain your pool past this safety depth, call your pool technician first!

Knowing all this information, you may realize your pool liner needs to be replaced. We would be a happy to assist you with any pool liner questions as well as helping you DIY install one in your pool.